This is the ultimate guide to BOV in 2025.

So if you want to learn:

- What BOV is;

- If your product can be packaged in BOV;

- How to select the correct BOV;

- Where to buy the BOV package and BOV filling machinery;

- What you need to get your project started.

Then you’ll love this new guide.

Let’s get started.

Contents

Chapter 1

Bag on Valve(BOV) History

In this chapter, we’re going to walk you through the history of BOV.

You will learn when and who invented and developed it.

You can also have the chance to see the prototype of those interesting products more than a hundred years ago.

Sounds great, right?

Without further ado, let’s get right to the point.

It’s interesting that industrial development also follows the theory of evolution.

The various automobiles of today were not invented suddenly but were based on the first car invented by Karl Benz.

Karl Benz successfully developed the first automobile in October 1885, which set the tone for the design of automobiles, and even today’s cars cannot escape from this framework.

The same applies to the BOV package.

Before the emergence of binary packaging, there were already basic products on the market and some related research.

1790:

The concept of aerosol was originated when a kind of self-pressurized carbonated beverage was introduced in France.

1837:

A soda siphon equipped with a valve was invented by a man called Perpigna.

1837:

A soda siphon equipped with a valve was invented by a man called Perpigna.

1862:

People already tried to make an aerosol can from metal material and did a lot of testing.Unfortunately, this idea failed commercially in the end due to its enormous size.

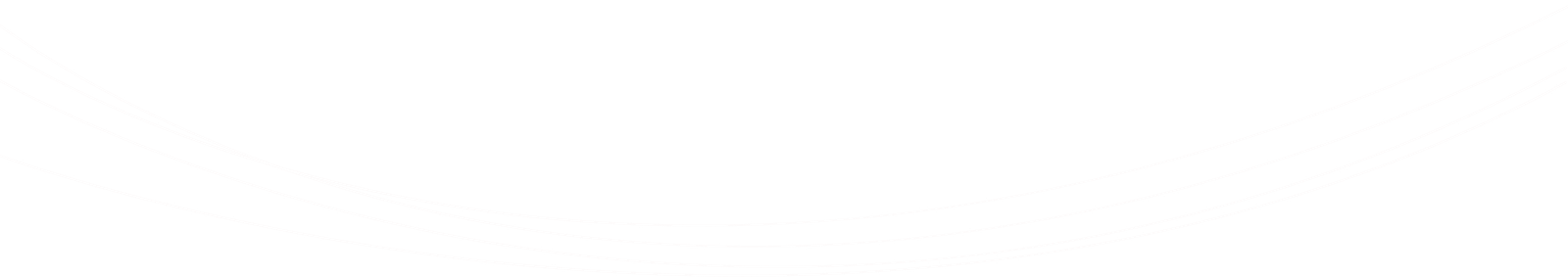

November 23-1927:

A Norway engineer called Erik Rotheim applied the patent for the first aerosol spray canand valve. This can be seen as the pioneer of modern aerosol cans and valves.

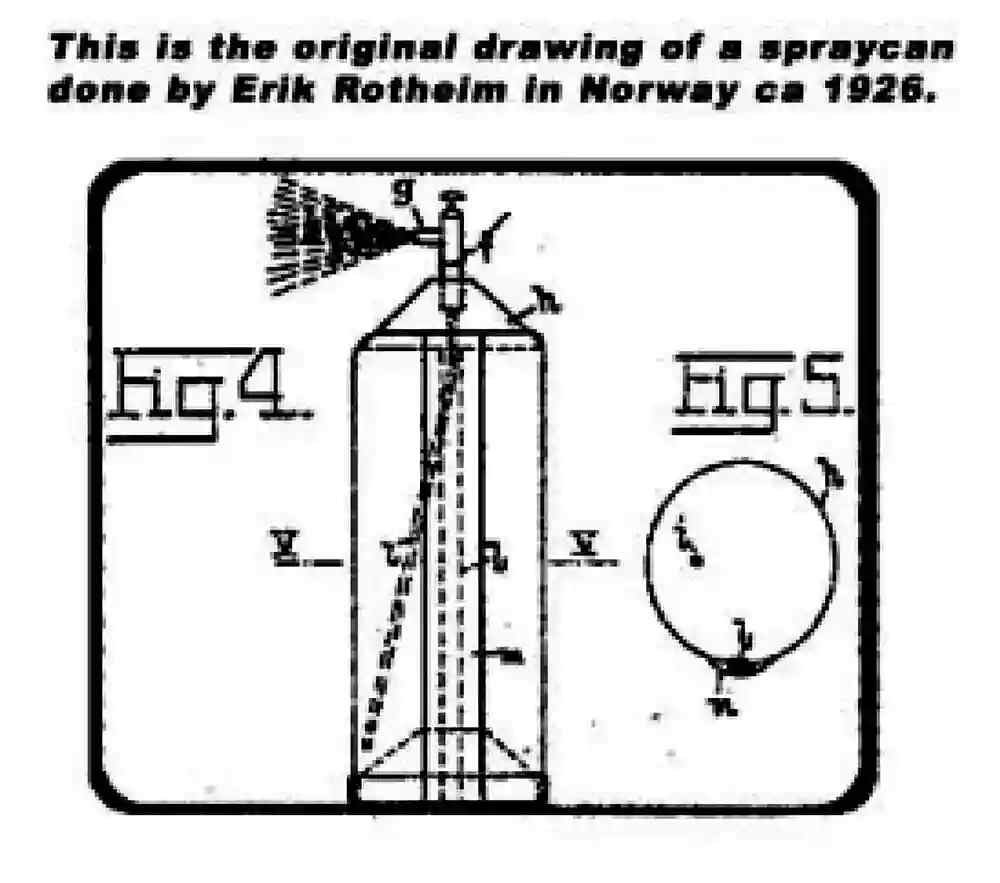

1943:

Lyle Goodhue and William Sullivan from the United States developed a small aerosol withpropellant liquid gas(a fluorocarbon).

1949:

Robert H. Abplanalp invented a valve to allow the crimping to happen on the valve, whichcan deliver the liquid content through the pressure from inert gas.

1953:

Robert H. Abplanalp filed his crimp-on valve patent, which helped his Precision ValveCorporation start mass production. This symbolizes the beginning of the modern aerosolvalve.

1982:

The first BOV design patent was filed in Europe. And citric acid and sodium bicarbonateare used for the propellant purpose.

July 25 – 1985:

NASA delivered a Pepsi beverage that used BOV package through the Space Shutter –Challenger. However, the astronauts did not like it.

1986:

Eco-Pack from Belgium firstly applied compressed air or Nitrogen as the propellant gasfor the BOV package.

Chapter 2

What Is BOV?

BOV is the acronym of Bag On Valve. It’s a term in the aerosol spray industry. Actually, it is necessary to distinguish between BOV and BOV packages when we talk about them.

BOV is literally a 4-layer-film bag(or pouch) welded to an aerosol valve.

It is only a component of the complete BOV package or system, including BOV, bottle, actuator, and cap.

It’s simple logic, right? Then let’s further dive into each of them.

Further Clarification of BOV Package

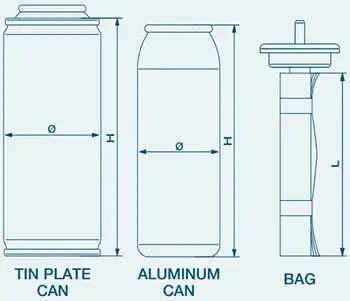

1. Can

The can or bottle is the most visible part of a BOV package.

It is crimped by the BOV at the can opening, in which a sealed container is formed.

The unique feature is that this container has two chambers. One chamber is the 4-layer-film bag(pouch), and it contains the product material of liquid, gel, or gas.

The other chamber is the space between the bag outside and the bottle inside.

This chamber carries the propellant gas of compressed air or Nitrogen.

The bottle can be divided into three categories according to material: tinplate, aluminum,and PET. Aluminum cans are used the most because most BOV package is applied in high-end products like cosmetics and pharmaceuticals.

In recent years, PET can has been used more widely in the BOV package.

2. BOV

BOV plays the most important role in the BOV package system.

It is also the origination of the BOV package’s multiple advantages.

It’s safe to say that you can basically master the BOV package system once you understand BOV in depth.

BOV Type

BOV can be categorized into different types by different standards. Here below are some categorizing examples.

| Standard | Valve Size | Valve Type | Applications | Volume |

|---|---|---|---|---|

| Categories | 1 inch BOV | Male BOV | Regular BOV(usually for cosmetics,pharma, etc.) | 30~300ml |

| 20mm BOV | Female BOV | Special BOV(usually for fire extinguisherspray) | 500~600ml |

Bag Material

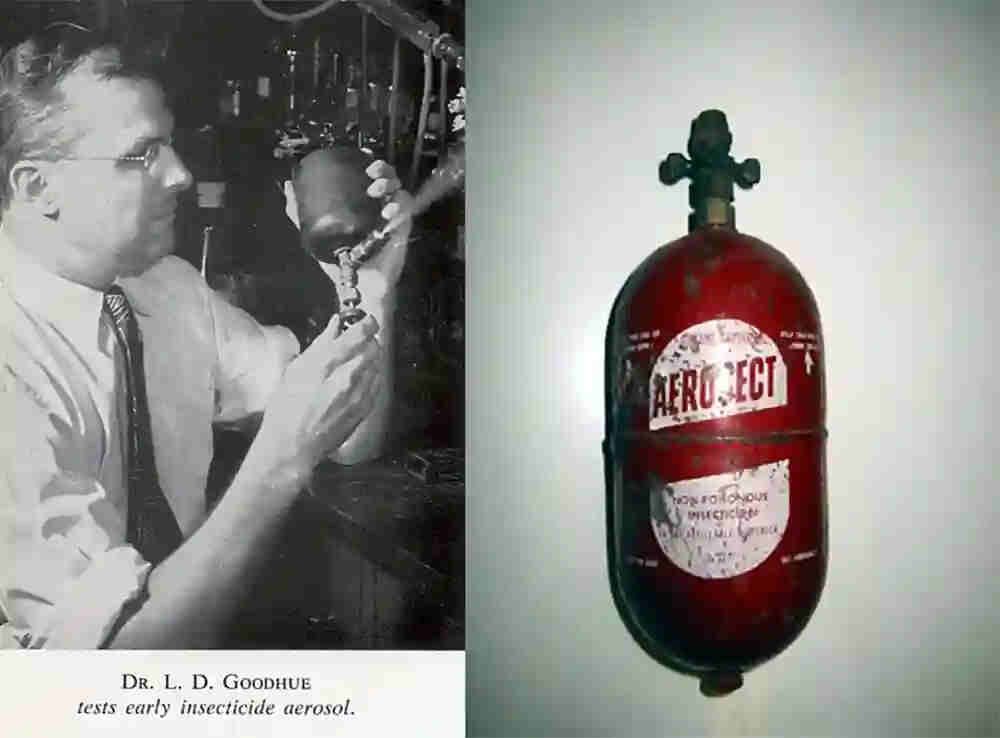

The BOV bag is made of a 4-layer film. The material of each layer is different and serves different functions. Each layer is stuck tightly together by the adhesive.

Layer 1 (PE):

The BOV bag is made of a 4-layer film. The material of each layer is different and serves different functions. Each layer is stuck tightly together by the adhesive.

Layer 2 (OPA):

It’s made of OPA Nylon, which features excellent toughness, puncture resistance, and outstanding resistance to oil, grease, and chemical solvents.

Layer 3 (Aluminum):

It has good barrier performance against moisture, light, oxygen, etc. And features high-temperature resistance, puncture resistance, and no deformation.

Layer 4 (PET):

It’s the outermost layer made of PET. It has good mechanical properties and good folding resistance. It performs excellently in blocking gas, water, oil, and odor. It’s non-toxic,odorless, has good hygiene, and can be directly used for food packaging.

Bag Size

The bag pouch size can be set according to the amount of filled product, and the can size. The bag pouch capacity is usually set between 30ml~40Oml, and special sizes can also be made according to the customer’s requirement, such as 500ml or more for the fire extinguisher.

Due to the slow filling rate of the bag valve, it is rarely used on large-capacity products. It can not be completely filled in the amount of filling and should allow the bag to maintain a certain percentage of space. The below table demonstrates the commonly used bag filling volume and the suitable can capacity matching it for your reference.

| Can Type | Can Size(mm) | Can Volume | Bag Filling Volume | ||

|---|---|---|---|---|---|

| Aluminum Can | Ø35*38 | 77ml | 2.6 oz | 30ml | 1 oz |

| Ø35*105 | 89ml | 3 oz | 50ml | 1.7 oz | |

| Ø40*125 | 140ml | 4.7 oz | 75ml | 2.5 oz | |

| Ø40*156 | 175ml | 5.9 oz | 100ml | 3.4 oz | |

| Ø45*125 | 175ml | 5.9 oz | 100ml | 3.4 oz | |

| Ø45*150 | 210ml | 7.1 oz | 125ml | 4.2 oz | |

| Ø45*190 | 270ml | 9.1 oz | 150ml | 5.1 oz | |

| Ø50*125 | 210ml | 7.1 oz | 125ml | 4.2 oz | |

| Ø50*156 | 270ml | 9.1 oz | 150ml | 5.1 oz | |

| Ø50*190 | 335ml | 11.3 oz | 200ml | 6.8 oz | |

| Tinplate Can | Ø45*96 | 140ml | 4.7 oz | 75ml | 2.5 oz |

| Ø45*118 | 175ml | 5.9 oz | 100ml | 3.4 oz | |

| Ø52*160 | 335ml | 11.3 oz | 200ml | 6.8 oz | |

| Ø52*195 | 405ml | 13.7 oz | 250ml | 8.5 oz | |

| Ø57*207 | 516ml | 17.5 oz | 300ml | 10.1 oz | |

| Ø65*195 | 650ml | 22 oz | 400ml | 13.5 oz | |

3. Actuator & Cap

BOV package can apply the standard aerosol actuators and caps. Of course, there are special actuators and caps to fit certain specific products like olive oil spray, saline nasal spray, etc.

Since the appearance of BOV, there have been two schools of thought about whether BOV is an aerosol or not. One school of thought is that BOV is an aerosol, and the other is not.

In my pinion, BOV can be seen as an aerosol, different from the traditional aerosol that first appeared.

Aerosol spray is a type of dispensing system which creates an aerosol mist of liquid particles. It comprises a can or bottle containing a payload and a propellant under pressure. When the container's valve is opened, the payload is forced out of a small opening and emerges as an aerosol or mist.

--- Wikipedia

The BOV packaged products match the definition on Wikipedia entirely. The unique feature is that the propellant in BOV is pure air or N2, which is different from the conventional fluorocarbon.

Plus, the pure air or N2 is not sprayed out at all together with the product, while the traditional aerosol products deliver the propellant as well once the product is sprayed out.

When we talk about it, it is more proper to refer to BOV aerosol and conventional aerosol(or non-BOV aerosol).

5 Types of BOV Packages

Various products are applying the BOV package.

With the development of technology and new product requirements, many new forms of BOV have emerged.

To sum up, there are the following five BOV package forms.

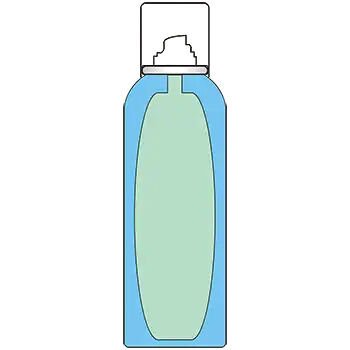

1. Typical BOV

This is the most commonly used type in the market. It is made of a tinplate can or aluminum can, with a 1-inch male or female BOV. It is applied in cosmetics, pharmaceuticals, fire extinguisher, etc.

2. 20mm BOV

It’s similar to the typical BOV. The difference is that the valve size is 20mm. It’s mainly suitable for use with pharmaceutical and cosmetic products.

3. PET BOV

This PET BOV has been introduced these years. It adopts a PET bottle with a 1-inch BOV made of plastic.

What is different is that the valve crimping is external while the typical BOV crimping is internal.

It is mainly used for cosmetics. But there is one obvious drawback of this type of package.

That’s temperature. It is possible to melt or easier to break once it is close to heat or fire.

4. Dual BOV

This new Bag-on-Valve package design was developed by Toyo & Deutsche Aerosol.

Literally, 2 BOVs are combined to be attached to one valve.

There are two pouches, and also each bag is equipped with one valve stem.

This package is mainly used for 2-component products. Once sprayed out, the two materials come out to mix together at the actuator.

5. Variant Dual BOV

Similar to this Toyo dual BOV, there is another type of dual BOV. It has two pouches that are independent of each other.

The first valve stem is nested inside the other valve stem.It’s also mainly used for 2-component products like shaving foam.

3 Types of BOV Products

There are 3 types of BOV package products.

1. Hydrocarbon BOV

The most common products packaged by BOV in the market contain two parts. One is the product inside the bag, and the other is the propellant(compressed air or Nitrogen) in the can.

But there are some other BOV packaged products containing liquid gas propellants(mainly Hydrocarbons). In this case, these types of BOV packaged products are categorized into Hydrocarbon BOV products.

One typical example is post foaming shaving foam spray. Apart from the shaving gel, another product(isopentane) is to be filled inside the bag. Once the consumer presses the button to release the product, the mixture of gel and isopentane can achieve an excellent foaming effect.

Another typical Hydrocarbon BOV product is nail gun cell cartridge. It’s a slim narrow canister(usually 30mm diameter) with an one inch BOV pouch inside. Inside the canister(but outside the pouch), there is the butane gas. Inside the pouch, there is the propane gas.

2. Standard BOV

This standard BOV uses only air or Nitrogen as the propellant to propel the products out from the bag.

There is only one bag attached to the valve. Such BOV products make up the vast majority of the market.

3. Non-Spray/Low-Pressure BOV

The products in the above two types are dispensed in a spray pattern, which means the product is atomized.

But the non-spray/low-pressure BOV products do not spray at all. The products are delivered only in gentle pouring style.

Therefore, they only require low pressure of air or Nitrogen in the container(2~6 psi), which is enough to compress the bag to release the product.

These products include wound washes, eyewash, coffee, tea, etc.

4. Other Variants Similar to BOV Package

One distinctive type is the piston can.

BOV package is a container containing two separate compartments by the bag film.

The piston can is a sealed container of 2 chambers separated by the piston.

Above the piston is the product, and below the piston is the propellant gas(usually liquid gas).

The product is filled into the can through the can opening, and the propellant gas is filled through the needle or plug hole at the can bottom.

Chapter 3

How BOV System Works?

BOV system is a special method of delivering products.

Just seeing from the outside appearance, BOV and ordinary aerosol products are not very different.

Both spray the product through atomization.

But the working principle of BOV system is very different from that of ordinary aerosols.

Let’s check it out.

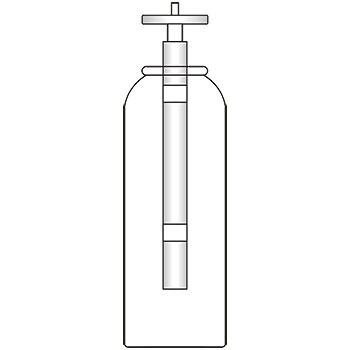

BOV System Is A Dual-chamber System

In the aerosol industry, there are many dual-chamber or barrier type package types, including bag on valve(BOV), piston can system, and bag in can system.

The 2 chambers are for liquid product and propellant gas respectively. This dual-chamber design brings the benefit of isolating the product from the propellant gas. This is a super ideal solution especially for products like food and pharma.

Piston Can Barrier Package System

It is an aluminum can with a piston inside.

The liquid material is filled normally into the upper chamber and the sealing is achieved by an one inch aerosol valve.

The propellant gas is filled via needle or plug at the bottom.

It is compatible with liquid, oil, cream, grease and highly viscous products.

Bag in Can Barrier Package System

It’s similar in filling to the piston can system, but different in the structure.

The inner bag or can is mainly aluminum, and it is attached to the outer can at the upper area. So, the liquid material is filled normally into the inner bag in a normal way.

There is also a hole or plug at the outer can bottom for the propellant gas to be filled.

It is particularly suitable for viscous products.

Can in Can Barrier Package System

This type is different from above two. It’s mainly applied in two-component paint spray.

It’s more like a normal aerosol package plus an extra can inside. This small can or container is attached to the outer can bottom.

This inner chamber contains hardener(Catalyst), and the outer chamber contains the paint and propellant gas.

The inner chamber is broken to release the hardener to mix with the paint via plugging the bottom area.

Bag on Valve Barrier Package System

Compared to above 3 barrier package systems, bag on valve is the most commonly used in the market. It is a little bit different from the bag in can system.

Bag on valve is a combination of the 4-layer film bag and a standard aerosol valve. The bag is usually made of PE, OPA, ALU and PET stuck tightly together to each other by the adhesive.

Different from the bag in can system(bag is attached to the can opening area), the bag is attached to the aerosol valve in BOV barrier package system.

Besides, the gassing and crimping has to be done prior to the liquid filling. After gassing and crimping, the liquid is pressure filled into the bag through the valve stem.

BOV package and conventional aerosol package can deliver the products out because of the pressure inside the can. The pressure originates from the propellant gas inside.

There are two categories of propellant gases in this industry. They are liquefied gas and compressed gas.

| Gas Type | Gas Name |

|---|---|

| Liquefied Gas | Butane |

| Propane | |

| n-Butane | |

| DME | |

| CFCs | |

| Compressed Gas | Carbon Dioxide |

| Nitrogen | |

| Nitrous Oxide | |

| Pure Natural Air |

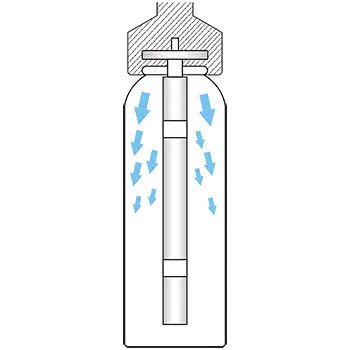

The propellant gas applied in BOV is usually Nitrogen.

The channel between the liquid product and the atmosphere is opened as the actuator is pressed.

The pressure from Nitrogen forces the liquid to come out. The liquid is dispersed evenly via instant strong pressure and channel of the actuator.

There are two points which we need to pay attention to.

1. The pressure will drop as the product is delivered because the space forNitrogen is increased. But this pressure drop will be compensated by the high pressure of Nitrogen filled.

2. The propellant gas Nitrogen will never come out of the can, even after the liquidproduct is dispersed completely.

Besides, as you can see that the bag inside the can is actually surrounded by the propellant gas Nitrogen, the pressure applied to the bag overall surface is same and even.

Therefore, the liquid product can be delivered out at any angle, even upside down. This feature brings a lot of convenience to the end consumer.

Chapter 4

How BOV Packages Your Products?

BOV package is different from the traditional aerosol package.

There is no doubt that it must be filled in a different way as well.

In this chapter, you will learn each and every step of how your product is packaged in a BOV barrier system.

There are generally the following procedures below for BOV products packaging in theactual production process.

1. BOV Inserting

The valve is inserted into the can after the liquid is filled into the can for conventional aerosol production.

Obviously different from the traditional aerosol production, the valve together with the pouch attached is inserted into the empty can first for the BOV products packaging process.

This procedure can be done by humans manually or machines automatically.

2. UTC Gassing & Crimping

The valve will be vacuuming sucked to get lifted to allow a small space between the valve and the can opening.

Then the propellant gas(compressed air or Nitrogen) is propelled into the can through this small space.

After that, the valve comes down to touch the can opening. Last, the valve is crimped to the can opening.

All these steps are completed under the same cup. Therefore, it is called UTC(Under The Cup) technology. At the same time, the pressure-filled inside the can is able to be measured by the machine.

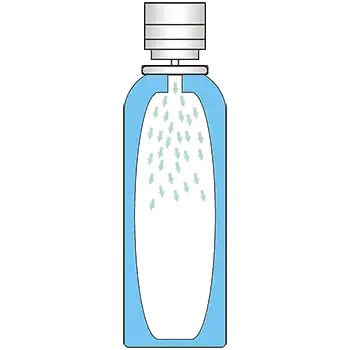

3. TTV Pressure Liquid Dosing

The liquid or viscous product is filled Through The Valve(TTV) stem into the bag. There is already pressure inside the can, so the liquid product is dosed with strong force.

Until now, the primary packaging work is finished. But there are still some other steps to follow to get finished products for putting on the shelf.

4. Weight Checking

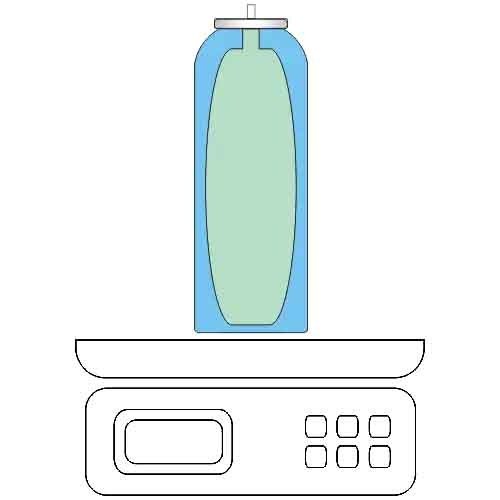

This step can be done by humans or by machines. Its purpose is to check if the filling volume of the product is targeted. It’s a step for quality control.

5. Leakage Checking

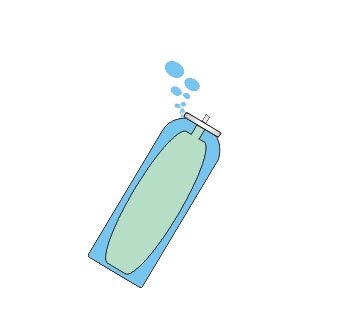

As you know, the product is a pressurized can of 0.4~1.0Mpa(58~145 psi), usually inside.

There is the possibility of leakage.

It’d be a disaster for the seller if a serious leakage issue happened in the market.

The traditional leakage checking method is through hot water(50~55℃) bath.

The finished cans pass through the hot water for 3 minutes to sort out the leaking cans with bubbles.

In my view, for aerosol products using traditional liquefied gas propellants (butane, propane, LPG, DME, R134a), the hot water bath leakage test can be quite effective.

This is because the saturation vapor pressures of these propellant gases increase rapidly with rising temperature. After 3 minutes of immersion in 50°C water, the internal pressure of the can increases significantly, effectively exposing any potential leaks.

However, for BOV packaged products using nitrogen (or natural air) as the propellant, the conventional water bath test may not be as optimistic. This is because the saturation vapor pressure of nitrogen does not change significantly with temperature.

For very minor, intermittent leaks, they may be difficult to visually detect as the can moves in the water bath, since the leaks are too small.

As an alternative to the standard water bath leakage test, laser spectroscopy microleak detection can be used to identify these more subtle leaks. You can read more in the following chapter 10.

6. Actuator and Cap Placing

In this final stage, the actuator and cap are applied to the can’s top, completing the process. This task can be executed either manually or automatically, offering flexibility in production methods.

Watch the video to see how the entire process unfolds. It will give you a clear visual understanding of the workflow.

Chapter 5

Benefits of BOV

BOV package is becoming more and more popular, and the market is gradually expanding, thanks in large part to its many advantages.

The following is a list of some of the benefits from different perspectives.

Let’s check it out.

1. Safety & Environmental Benefits

1) Environmentally Friendly

The products utilize propellant gases such as pure air or N2, which are non-VOCs and non-greenhouse gases, contributing to environmental sustainability.

2) Health-Conscious Design

Packaged within a vacuumed food-grade bag, theproduct requires fewer preservatives, promoting a healthier option for consumers.

3) Safety Assurance

The non-flammable gas used in our products eliminates risks associated with explosive issues, unlike Hydrocarbons, ensuring user safety.

4) Hygienic and Sterilizable

Encased in a 4-layer laminated pouch, theproducts offer superior barrier protection and impermeability, enhancing hygiene and allowing for sterilization when needed.

4) Temperature Resilience

The use of compressed air or N2, inert gases, ensures stability in pressure even with varying ambient temperatures, providing consistent performance regardless of environmental conditions.

2. End-User Benefits

1) High Empty Rate

Achieving up to 99.9% empty rate ensures that as a consumer, you utilize the entirety of the product, leaving almost no content wasted.

2) 360° Spray Capability

This feature allows for spraying at any angle, even upside down, thereby minimizing product misuse.

3) Uniform Spraying Pattern

With BOV technology, users can achieve an even and controlled spraying pattern for optimal results. This precision ensures smooth and consistent dispensing, offering users precise control over product application.

4) Quiet Operation

The advanced technology ensures silent spraying performance, reducing the noise typically associated with propellant discharge.

5) No Pumping Required

Eliminating the need for a pumping motion, users can enjoy continuous spraying without the hassle of repeatedly pressing the actuator.

6) Enhanced User Comfort

By eliminating the presence of gas alongside the product, this design reduces chilling effects often experienced with traditional aerosols, enhancing user comfort during application.

3. Manufacturing & Sale Benefits

1) Extended Shelf Life

The isolating bag technology effectively separates products from gases and air, prolonging the shelf life of oxygen-sensitive items. This feature not only benefits the products but also reduces costs for sellers.

2) Versatile Compatibility

This system accommodates both liquid and viscous products, such as gels, expanding application possibilities and creating new business avenues.

3) Ease of Integration

Compatibility with standard actuators and aerosol cans eliminates the need for specialized tooling, streamlining the manufacturing process.

4) Cost Efficiency

The non-flammable and non-explosive nature of the gas eliminates the need for a separate gassing room, saving on infrastructure costs for businesses.

Chapter 6

Applications of BOV

BOV supplies the market’s increased interest by giving old products new and improved, more convenient applications.

In some specific applications, it has to be BOV to make it. It also helps establish niches for new products.

Here below are some proven uses for BOV technology.

1. Cosmetics

- Sunscreen spray

- Lotions

- Shaving foam

- Mineral water facial spray

- Self-tanning spray

- Personal hygiene

- Nasal spray

- Tattoo aftercare spray

- Wound care gel spray

- OTC products

- First aid spray

- Baby care spray

2. Food & Nutrition

- Cooking oil spray

- Liquid flavorings

- Salad dressing

- Liquid tea and coffee

3. Veterinary & Pet Care

- Equine wound washes

- Anti-fungal spray

- Flea & tick spray

- Hair polish & detangler

- Leather cleaner & conditioner

4. Miscellaneous

- Liquid fire extinguisher spray

- Air freshener

- Insect repellent

- Hunting products

- Disinfectant

- Furniture polish and cleaner

We see that BOV can be applied in numerous fields because of its outstanding benefits.

Then, can all products be packaged in BOV?

The answer is NO.

There are some specific products that cannot be applied on BOV for the time being.

They are dry powders, paints, glues, and hairsprays. But water based paint can be packaged in BOV container.

Chapter 7

Difference: BOV v.s. Conventional Aerosol

There are various aerosols on the market, covering all industries.

Some are ordinary aerosol packaging, and some are BOV packaging.

Then, what is the difference between these two packaging products?

1. Product and Propellant Remaining Condition

In traditional aerosol products, the liquid and propellant gas are housed in a single container, resulting in both being dispensed together during use.

In contrast, for BOV packaged products, the liquid or viscous content is stored in the bag separately from the propellant gas.

This segregation ensures that the propellant gas remains within the container and does not mix with the liquid content during spraying, maintaining product integrity and performance.

For conventional aerosol products, three distinct machinery functional heads are utilized for their filling processes:

1. Liquid Filling Head

Used to fill the empty can with liquid content.

2. Crimping Head

Responsible for sealing the can with the valve.

3. Gassing Head

Fills the propellant gas through the valve stem.

Above is a lab type aerosol filling machine from Zigler. From left to right, you can see liquid filling head, crimping head and gassing head.

In contrast, for BOV products, only two machinery functional heads are required due to the unique technology involved:

1. Gassing & Crimping Head

This head is responsible for filling the gas into the empty can and sealing it with the valve using UTC (Under The Cup) technology.

2. Liquid Filling Head

Used for pressure filling the liquid material into the bag, ensuring the separation of liquid content and gas within the packaging.

Above is a laboratory-grade BOV filling machine from Zigler. On the left side, it is equipped for crimping and gassing using UTC technology.

On the right side, there are two functional heads. The first head is dedicated to liquid filling, which is the essential function. The second head is designed for cleaning the aerosol valve cup to eliminate any liquid residue, which feature is optional.

2. Propellant Gas

In the context of aerosol packaging, BOV (Bag-on-Valve) technology exclusively utilizes a single propellant, typically compressed air or nitrogen.

In contrast, traditional aerosol products employ various propellants such as butane, propane, refrigerants, CO2, among others, depending on the specific product requirements and formulations.

Chapter 8

How to Select BOV for Your Products?

BOV packaging is versatile and can be effectively used for a range of products.

Here are some guidelines to help you identify the most suitable BOV package for your needs.

1. Match the Pouch with the Can

The pouch is rolled and secured with one or two adhesive tapes. It will expand fully once the liquid product is filled into the bag. The pouch dimensions must be compatible with the can after liquid filling. If the pouch is oversized, there is a risk of it breaking.

Additionally, it is important to align your product image with the type of can used. Typically, aluminum cans are considered more luxurious and are preferred for cosmetics and pharmaceutical applications over tinplate cans.

2. Match the Pouch Volume With the Product Volume

It is crucial to consider the pouch capacity (volume) when selecting it for your product. It is recommended not to fill the pouch to its maximum capacity. It is advisable to leave a minimum of 10% to 20% of space unfilled.

For instance, if your target product volume is 50ml, the pouch capacity should be between 55ml to 62.5ml. Filling the pouch to its full capacity increases the risk of breakage if the can is dropped or impacted.

3. Match the BOV With Your Product's Specific Properties

Some special BOV is required when it comes to some specific applications. For example,the pouch volume should be big enough to contain more liquid products for portable fire extinguisher spray.

Besides, the bag inside dip tube should be broader, and more big holes should be applied to the dip tube for quicker liquid flow into the bag instantly during the liquid filling process.

4. Match the BOV Actuator With Your Product Specific Properties

Different products may necessitate varying spray patterns. For a mineral water facial spray, the actuator should provide a fine and soft product delivery pattern to achieve a tender, moisturizing touch for the consumer.

In contrast, for a portable fire extinguisher spray, the actuator should enable a strong and wide spraying pattern to extinguish fires quickly from a distance of 2 to 3 meters away.

Chapter 9

Quality Check of BOV

Quality control is crucial in the production of Bag-on-Valve (BOV) packaging to ensure optimal performance.

The BOVs undergo rigorous checks at various stages to guarantee high quality.

Before leaving the factory, all BOVs must pass the factory’s stringent quality inspection process.

Below are some key items from the appearance checklist used during the quality check:

- Check for the presence of the spring, stem, chamber, inner/outside gasket, and sealing ring.

- Verify the presence and condition of the dip tube, ensuring it is not blocked, cracked, excessively dirty, or missing.

- Inspect the bag for any defects such as breakage, scratches, scaling, bubbles, sand holes, lack of vacuum sealing, leakage, or uneven cutting.

- Ensure tight and even hot sealing between the bag and the chamber, without wrinkles.

- Check for any damage to the inner or outer gasket.

- Confirm that the dip tube is correctly positioned.

- Ensure that the ribbon is securely fastened.

- Verify that the colors of the stem, chamber, mounting cup, etc., match properly.

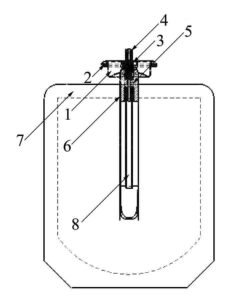

| Part Number | Component | Drawing |

|---|---|---|

| 1 | Mounting Cup |  |

| 2 | Outer Gasket | |

| 3 | Inner Gasket | |

| 4 | Stem | |

| 5 | Spring | |

| 6 | Housing | |

| 7 | Bag | |

| 8 | Diptube |

Additionally, during the development and production phases, other tests such as pressure testing and pull testing are conducted to simulate real-world working conditions and further ensure the reliability and quality of the BOV packaging.

These tests help identify any potential issues early on and guarantee that the BOVs meet the required standards for performance and durability.

Chapter 10

Quality Check of BOV Packaged Products

During the production of BOV products, many quality checking actions have to be done to ensure that the finished products are also qualified.

Below are some methods that the factories would apply.

1. Leakage Check

BOV packaged products are a container with product material and propellant gas-pressurized inside. Multiple times of atmospheric pressure inside the can makes it possible to leak.

It’s necessary to check the potential leakage before launching the finished products into the market.

There are 3 types of leakage checking.

A. Water Bath Leakage Check

The principle is simple: bubbles generated from leaking cans will surface when immersed in hot water. The water is heated and maintained at 50-55℃, and cans are submerged for 3 minutes to detect bubbles. This process can be carried out manually or automatically.

For small daily production volumes, a manual water detection device may suffice as bubbles are easily observable. However, in automated production lines where cans swiftly enter the water tank one after another, accurately detecting leaks becomes challenging. The movement of cans in water causes ripples hindering bubble observation, and slow, small leaks are difficult to detect.

Moreover, this method is impractical because BOV propellant gas in aerosol cans is typically air (70% nitrogen) or pure nitrogen, which exhibits minimal pressure changes with temperature increase or decrease. Incremental pressure from temperature rise is often insufficient to reveal hidden leak points.

Consider the strain of requiring a worker to vigilantly watch for bubbles on the water’s surface for 8 hours daily—it is impractical and unsustainable.

B. Can Interior Pressure Check

In addition to the water bath method, an interior pressure check can also be utilized to detect leaks. If there is leakage, the pressure inside the can will decrease. You can manually measure the internal pressure of the finished product using a pressure gauge or automate the process with a machine.

This method works well for low-viscosity products; however, it poses challenges for high-viscosity products.

The principle involves a working head contacting the valve to open it, connecting the bag and the working head channel to allow material flow into a chamber for pressure sensing.

For precise pressure sensing, the channel and chamber need to be as small as possible. With high-viscosity products, chamber can easily clog, potentially damaging the pressure sensor.

C. Laser Spectroscopy Microleak Detection

In addition to traditional water bath leak testing, there is also a method that uses laser technology to detect micro-leaks in cans quickly and efficiently.

The principle is that when an aerosol can passes through the detection area, the gas leaking from within the can is released into this area. The leaked propellant gas absorbs specific wavelengths of infrared laser energy. The device’s built-in high-sensitivity sensor can accurately detect changes in the energy intensity of the laser beam after it passes through the detection area (i.e., how much light has been absorbed by the leaked gas). The system analyzes the sensor signal in a very short time (about 20 milliseconds). If a change in light absorption caused by the leaking gas is detected (indicating that a leak exists), the system will immediately send a signal. This signal triggers subsequent rejection devices on the production line, accurately removing the problematic can from the line. Compliant cans are unaffected and continue moving forward.

However, this method has a drawback: it is ineffective for BOV(bag on valve) packaging. This is because BOV packaging is filled with pure nitrogen or compressed air. Whether it’s pure nitrogen (which makes up 78% of air) or compressed air, even minor leaks are nearly impossible to detect with laser technology. Even companies like Emerson and Ranr in the UK, which possess such micro-leak detection devices, only use propellant gases such as Butane, Propane, LPG, N2O, CO2, DME, R1234ze, R134a, R227, and 152a, excluding pure nitrogen or compressed air.

2. Weight Check

This step is to check if the product filling volume is targeted. You can do it manually with an electronic scale or automatically through a weight check machine. Any cans out of the weight value range would be kicked out automatically as the defective products.

3. Performance Check

Strictly speaking, this step is generally required before mass production. Of course, a random check can be taken during and after production to ensure that the entire batch is qualified.

The performance check would cover:

Spray Pattern

Check if the spray pattern is finely atomized or streamlined.

Spray Distance

Some products like fire extinguisher spray require a certain spray distance.

Product Emptying Rate

Use an electronic scale to measure the can weight before and after spraying and compare the two values.

Drop Test

Drop the can from 1.5 meters high and check if the bag is broken.

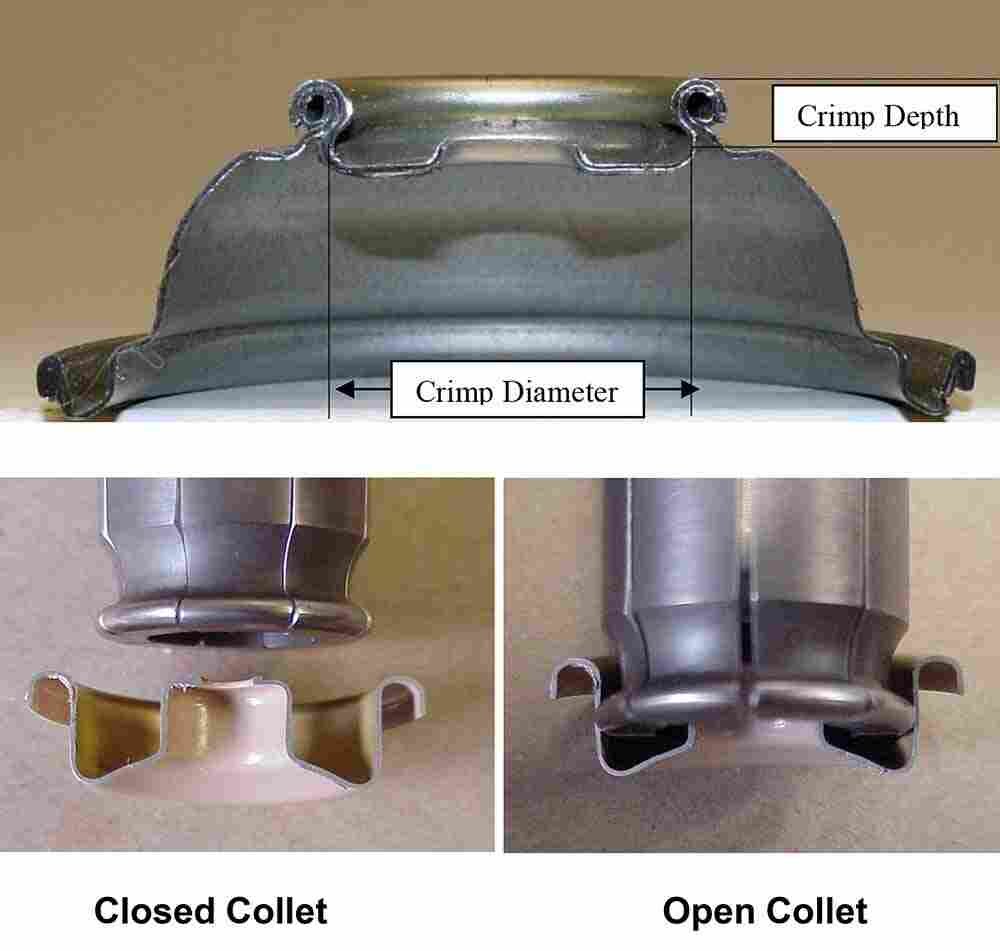

4. Crimp Diameter and Depth Check

This step should be executed both before and during production, serving as a troubleshooting method as well. Crimping parameters, encompassing crimping diameter and crimping depth/height, play a vital role in can sealing. Incorrect values in these parameters often lead to leaks.

Typically, the recommended crimping parameters are 5.1~5.2mm for depth and 27.1~27.3mm for crimping diameter.

Bonus Chapter

What Preparation You Need to Get Started Your Project

If you are a new comer thinking about a business opportunity of using BOV package, this chapter provides a check list of each aspects for you to follow.

You can refer to this list to consider if the business is workable, or start the preparation job. I’m sure that it can save you time and some cost.

1. Product Formulation

You have to know the recipe of the product you want to make. You may be able to find recipes online, or your friends may be able to share them with you.

But please note that you need to do tests to verify, because many recipes may not be the best for your market. For example, some ingredients may be expensive to source in your local area or not easy to find, which inadvertently increases the cost of your product.

You can verify through testing if you can use some alternative ingredients that are easily found in your market, with the same effect, but at a lower cost and easier to obtain.

2. Product Ingredients

These ingredients are all that make up your product.

For some, you can buy in your local market or import from abroad; for some others, you may need to blend.

Especially for some semi-finished ingredients, you need to process into finished products by yourself or a third party factory.

Product raw materials include, in addition to liquid materials, propellant gases, such as nitrogen, which are readily available at local gas stations.

3. Production Plant

Regardless of the size of your business, basic production facilities are required, including production areas, raw material storage areas, finished product storage areas, etc.

The size and planning of the plant can be arranged with reference to the actual equipment and materials needed to occupy the area. Generally, the area of the plant is 40~50 square meters when the business starts.

Since it is production, it is certainly necessary to pay attention to the requirements of the production plant, including electrical, fire, ventilation, etc.

4. Production License

Regardless of the country or region, legal production needs to first obtain the production license issued by the government. You need to consult with the local government authorities on what documents are required to obtain the production license.

Of course, you will also need to register your company or trademark, if you want to formalize your business.

5. Manufacturing Equipment

Generally you will need the following equipment.

- BOV(Bag-on-Valve) filling machine

- Material processing equipment (to process all raw materials into finished materials that can be filled). These generally include homogeneous emulsifying mixers (to mix or emulsify materials), water treatment equipment (to obtain high purity water),dispersing machines, etc.

- Other equipment, including production date printing machine (the production date will be printed to the bottom of the can), labeling machine (place the label stickers on the can body), heat film shrinking machine (the can body will be shrinked with a layer of film), sealing machine (sealing cartoon boxes), etc.

6. Package Stuff

These usually include:

- BOV packaging cans and valves

- Cartons

- Labels

- Shrink films

7. Personnel

Generally for the first production of small-scale manufacturers, 3 to 5 people can start your business. When the business gradually grows, you can consider increasing production capacity and hiring more workers.

Conclusion

This article shares BOV packaging systems knowledge from multiple perspectives, including the history, components, how it works, filling principles, and how to select, etc.

I hope it is of value and joy to you.