Table of Contents

This is an article to share some insight of lipstick production.

So, if you want to learn about:

- What molds are used in lipstick production

- What are the common defects in lipstick filling

- How to avoid the defects

You’ll love the examples in this post.

Lipstick Filling Mold Classification

From the perspective of molds, the mainstream categories in the industry can be divided into metal molds and silicone molds.

Metal Molds of Lipstick Filling

The metal molds used for lipstick filling are mainly divided into ejection molds and blow molds.

Ejection molds: They are mainly suitable for lipstick packaging materials with slanted surfaces, smaller inner cup diameters, and pen-shaped lipstick packaging materials. They can match softer lipstick formulas and can be used to produce layered lipsticks, slim lipsticks, and lipsticks with slanted surfaces.

Blow molds: They are suitable for classic lipstick packaging materials with inner cup diameters of 12.1mm / 12.7mm. The lipstick formula used with blow molds needs to be relatively firm.

Silicone Molds of Lipstick Filling

Silicone molds are a popular type of lipstick filling molds that have emerged in recent years. Lipsticks produced with silicone molds have a beautiful appearance and versatile shapes.

However, due to the potential interaction between the silicone material and the various oils and fats in the lipstick formula, higher requirements are placed on both the lipstick formula and the silicone material.

In addition, silicone molds have a certain lifespan. The shorter the lifespan, the more intermittent the production process, and the lower the stability and efficiency of the production process.

Unlike skincare products that prioritize efficacy, the appearance of cosmetic products is widely emphasized.

This poses a higher challenge for the lipstick filling process.

The Defects in Lipstick Filling

1. Black Spots or Foreign Particles

The possible causes of black spots or foreign particles include:

- Foreign particles introduced through electroplating debris or static electricity in the packaging material.

- Inadequate cleaning of the molds.

- Incomplete dispersion of color powders.

- Raw materials in the formula containing foreign particles.

The corresponding solutions would be to improve the dust removal rate of the packaging material, enhance mold cleanliness, and optimize the blending process.

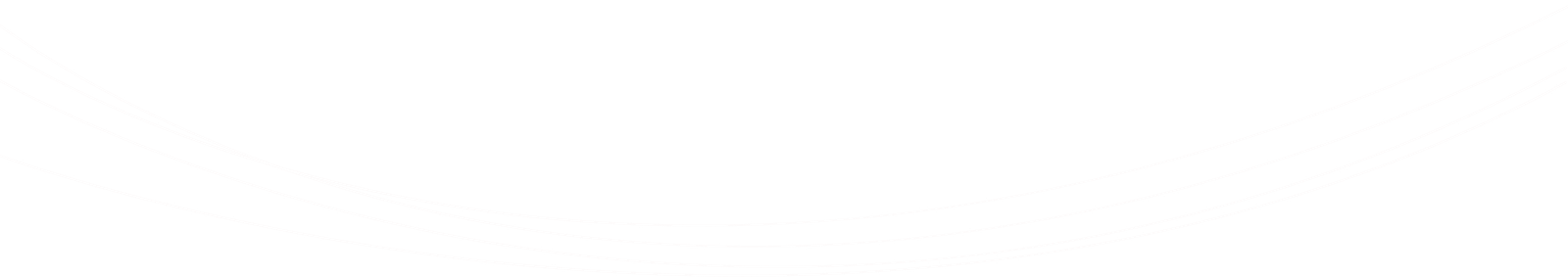

2. Wall Scraping

The “wall scraping” defect in lipstick filling refers to the phenomenon where friction occurs between the lipstick paste and the container walls during the filling process, resulting in surface scraping or scratches on the lipstick paste.

This defect can impact the overall appearance and quality of the lipstick, making the surface uneven or flawed.

The wall scraping defect is typically caused by improper filling equipment or processes, such as excessive filling speed, inappropriate filling pressure, or inadequate surface treatment of the container walls.

To avoid the wall scraping defect, optimization of filling equipment and processes is necessary, ensuring minimal friction between the lipstick paste and the container walls.

Are there any other reasons?

Certainly.

Especially when filling with adhesive packaging materials or when the paste is too soft, the possible causes may include:

- Insufficient concentricity of the packaging material.

- Incompatibility between the soft formula and the packaging material.

- Inappropriate storage and transportation conditions.

- Therefore, it is necessary to assess the compatibility between the paste and the packaging material during the development stage.

Additionally, different sales channels may require different storage and transportation methods.

It is important to proactively improve and control these aspects and conduct compatibility and stability tests, as well as drop and transportation tests.

3. Air Bubbles

The “air bubble” problem refers to the presence of bubbles or voids in the lipstick paste during the filling process.

These air bubbles can result in an uneven appearance of the lipstick and can affect the user experience.

The air bubble problem is typically caused by the following reasons:

- Insufficient mixing: If the ingredients of the lipstick are not thoroughly and evenly mixed, it can lead to the formation of air bubbles.

- Trapped air during filling: If air is not properly eliminated during the filling processdue to improper filling speed, it can become trapped in the lipstick paste, resulting in air bubbles.

- Low viscosity or high temperature:Low viscosity or high temperature of the lipstick paste can promote the formation of air bubbles.

To address the air bubble problem, the following measures can be taken:

- Thorough mixing: Ensure that the ingredients of the lipstick are thoroughly and evenly mixed to reduce the formation of air bubbles.

- Minimize trapped air: During the filling process, ensure proper elimination of air to reduce the occurrence of air bubbles.

- Control viscosity and temperature: Adjust the viscosity and temperature of the lipstick paste to minimize the formation of air bubbles.

4. Failure of Drop Testing

The reasons for the failure of drop testing are mainly related to the following aspects:

- Formula paste being too soft

- Insufficient gripping force of the inner cup of the packaging material

- Insufficient depth of the lipstick paste filled into the inner cup

- Excessive depth and size of shrinkage holes inside the lipstick paste

To address these issues, the formula paste should have a certain level of hardness and should not be too loose.

The gripping ribs of the inner cup should have a certain height and width.

There should be a controlled distance between the bottom of the paste and the bottom of the inner cup.

Additional measures such as re-melting or secondary filling can be taken to reduce the size of shrinkage holes.

The Filling Temperature for Lipstick Filling

The filling temperature for lipstick is typically set between 85-95 degrees Celsius.

This temperature range ensures that the lipstick paste can be filled evenly and effectively while avoiding overheating and degradation of the paste.

It is important to note that prior to filling, each shade of lipstick paste should be preheated for at least 2 hours to ensure complete dissolution and prevent any fatal defects such as breakage. The preheating temperature should not exceed 120 degrees Celsius to maintain product quality and production efficiency.

Difference In The Preheating Time and Temperature For Different Colors of Lipstick

The preheating time and temperature for lipstick paste may vary for different colors.

This is because different colors of lipstick may contain different pigments and ingredients, which can have varying chemical properties and melting points.

Therefore, to ensure that the lipstick paste of each color can dissolve completely and achieve optimal filling consistency, it may be necessary to adjust the preheating time and temperature.

In general, darker shades of lipstick may require a longer preheating time and slightly higher preheating temperature to ensure adequate dissolution of pigments and ingredients.

Conversely, lighter shades of lipstick may require a shorter preheating time and slightly lower preheating temperature.

The specific preheating time and temperature should be adjusted and optimized based on the formulation and process requirements of the lipstick manufacturer.

Through experimentation and practical production experience, the optimal preheating time and temperature for each color of lipstick can be determined to ensure complete dissolution of the paste and high-quality filling.